Blog

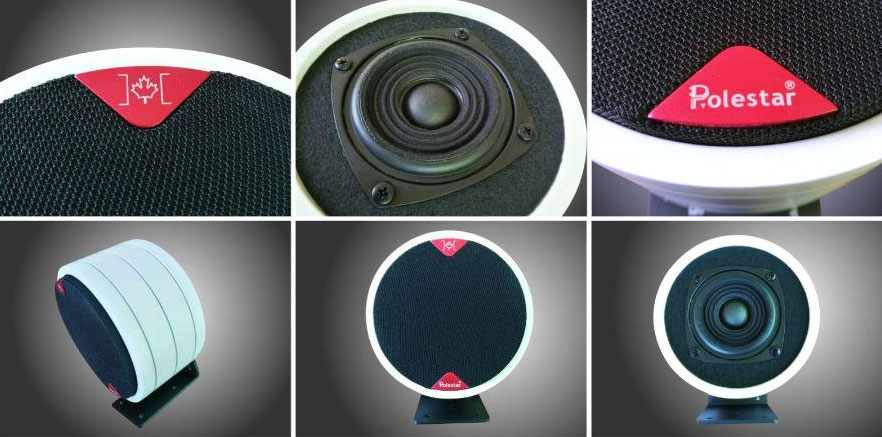

Polestar HT-1 Satellite speakers

The second generation has added venting ports that increase efficiency and makes the components easier to drive.

Palm-sized speakers are usually constructed out of plastic material due to the advantages of easy molding and low production costs. These lightweight cabinets however are prone to unwanted resonance and as such generally do not have good sound performance.

Aluminum cabinets can be slightly modified to give a sense of a high end product but due to the physical limitations of the material, it is difficult to match expectations. It is rare to see a wooden cabinet used for such a small speaker because of the high degree of precision required in manufacturing and of course the associated high cost. Nothing can beat the acoustics of a wooden cabinet though.

The sound stage is wide, deep and rich. The transient response is fantastic. As the strings of the guitar are plucked, the tension of the strings and the strumming of the instrument can be acutely experienced.

As the volume is increased the performance of the speaker does not break up and the vocals are still perfectly natural.

Though the HT-1 does not quite pack the punch of a large speaker, during the drum section the clarity of the drumsticks striking the drum skin and the elasticity of the reproduction lends a vivid and lifelike flavor to the experience.

The HT-1 has an adequate bass response and an additional small subwoofer will create a great 5.1/7.1 home theater or a small room 2.1 system.

A round cabinet design serves to break up the standing waves created inside the cabinet and produce a cleaning performance.

The roar and murmurs of a live audience along with the thunderous applause can all be clearly experienced.

The delicate sounds during the performance of a brass instrument are all fully detailed and the unique experience is not lost.

The second generation of HT-1 is more efficient and easier to drive while still retaining the original magnetic levitation quick reset system.

The primary diaphragm and sub diaphragm are made with different materials and also shape slightly differently. The diaphragms work in concert with each other to improve efficiency, stability and diffusion.